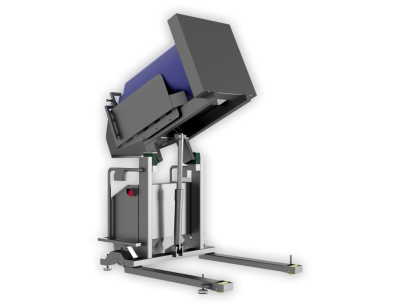

Tippers for barrels

TYPE BMB200

The BMB200 tipper is a model that has been designed to tilt barrels filled with both loose products and liquid. The standard tipper can operate with 200-liter drums. It is possible to adapt the device to drums with different capacities. The mobile base makes it possible to move the device between the halls. Stabilizing feet keep the machine level while operating.Tippers increase productivity, efficiency and save on labour.

| Specification: | ||

|---|---|---|

| Standard dumping height | approx. 1000 mm | |

| Max load | 600 kg | |

| Power | 400V or battery with charger | |

| Material | stainless steel | |

| Tipping angle | from 0° to 115° | |

| Basis | mobile on wheels with brakes | |

| Lowering signal | yes, sound | |

- BASISThere are 2 types of tippers - mobile and stationary. Stationary devices are put on 4 feet and level in the workplace. This solution is suitable for customers who will use the tipper in one place. If there is not enough space in the hall for the tipper to stand there "permanently" and you need to store it in the warehouse, or you need to move the machine between the halls, we offer a tipper on a mobile base on wheels with brakes. There is also an option to choose stabilizing feet that extend during operation.

- POWERBoxlifter offers two types of power supply: battery (with charger) or 400V mains. Battery-operated tipper allows operation in places where there is no constant power supply or the use of a cable is troublesome. The 400V mains supply, on the other hand, ensures more power of the tipper and is a guarantee of readiness for the device to work, even if the battery is not charged before.

- CONTROLBoxlifter tippers have two independent switches on both sides. This solution means that the devices are very adjustable and can workwith table. The cabled remote control allows the operator to control both the rate and the level of discharge.

- TIPPING HEIGHTBoxlifter tippers can tip over from 950mm to 1600mm. We can adjust the tipper to the required level. If there is a need to tip over to a greater height and it is not possible to ensure safe operation of the mobile tipper, we recommend using a pole tipper.

- LOADOur devices can lift up to 900 kg. If it is necessary to tip a heavier weight, e.g. 1200 kg, it is possible to add another cylinder. This solution allows for smooth and safe operation of the tipper.

- MATERIALAll Boxlifter tippers are made exclusively of stainless steel. It concerns each of the machine elements - wheels, constructions, cylinders and the dump tray. It is also possible to subject the entire device or some of its components to electropolishing.

- TILT ANGLEThe standard tilt angle of our tippers is 100 ° - 115 °. The customer's wish for this element is of course included in the design.

- ACTUATORBoxlifter uses own cylinders in its devices. This solution gives us confidence that the actuator has been selected correctly and is adapted to the appropriate loads.

- CONTAINER HANDLEThe container handle on our tippers is adjusted to be compatible with the rotated container. The customer decides on which side of the container it is to be gripped.

- LOWERING SIGNALINGEach tipper meets the OHS requirements and has an audible lowering signal. It is also possible to install traffic lights or a cover mesh that will further improve employee safety.

- WORKING TABLEIt is possible to design and make additional accessories, such as a transfer work table.

- LEGAL RESERVATIONSInformation on www.boxlifter.eu and in general offers may differ from the specifications of the machines offered for sale. This involves individual customer wishes and design changes. Boxlifter reserves the right to make changes to technical data and appearance of machines without prior notice. All data contained on our pages are for information purposes only and cannot be the basis for legal claims.